Longo Brothers Fruit Markets Inc. Web site notes that “attention to quality, freshness and goodness” is very much a Longo’s family tradition.

Executives at the Mississauga, Ont.-based grocery retail chain say to live up to this goal, all its stores need to be stocked with fresh produce, in the right quantities, in response to constantly changing customer demands.

But the scope of that mandate, they say, goes much further. It also means ensuring items in each of their stores meet Canadian safety standards, and that recalled products are removed from store shelves with speed and precision.

To accomplish this, the Ontario grocer has rolled out an enhanced product recall system from GS1 Canada. (GS1 Canada is a member of GS1, a global, non-profit supply chain standards organization).

Longo’s has 18 store locations in Ontario, as well Grocery Gateway, its online grocery business, which it acquired in August 2004.

The new GS1 Canada product recall program was officially launched Tuesday at a function in Toronto. Initially, the program is being implemented in the grocery sector, and a subsequent rollout to the general merchandise and pharmacy sectors is being planned for 2010.

READ RELATED STORIES

Canadian suppliers sweep out dirty data

Manitoba and IBM to track food ‘from farm to fork’

Longo’s says BizTalk is good for business

The cost of the program would depend on the size of the participating business, said Eileen Mac Donald chief operating officer, GS1. She said it would range from $250 to $1,700. “GS1 Canada will provide subsidies, on an ongoing basis, to ensure companies of all sizes can participate and no one is left out.”

Total [and timely] recall

Longo’s is one of the first major grocery chains to implement the enhanced system across all its 18 stories. Key expected benefits include streamlining and standardizing the process, especially communication between vendors and Longo’s recall coordinator. And this, it turn, is expected to significantly improve the speed and safety of the recall process.

“As a retailer, we need to ensure we have all the information required to execute a timely recall,” said Robin Maile, manager, food safety at Longo’s. “It’s also crucial that recall information is comprehensive and provided in a consistent format.”

Maile’s role at Longo’s encompasses all aspects of food safety — from regulations and compliance in stores to recall executions, from nutritional data and compilations, to dealing with customer food complaints.

When handling recalls, she said, standardization of communication between manufacturers/vendors and retailers is crucial.

As a grocery store that interacts with hundreds of vendors, she said Longo’s used to receive recall information in many disparate formats, such as e-mail, or through its category managers and so on.

“With the new online system all this information will now be accessed by our retail coordinators on a single online portal, so they don’t have to search in different areas to pull the critical pieces of data needed to execute a recall.”

Maile said the enhanced GS1 Canada Product Recall System doesn’t change the way Longo’s handles recalls at the store level.

“It does ensure that — as a reatailer — we get the critical information needed to execute the recall in a timely, accurate manner.”

Canadian retail organizations say standardization of recall information is one of the most useful features of the new system.

“Our members know that reputation and brand are linked to consumer confidence and protection, so they understand the importance of a strong product recall system, said Diane Briseboise, president and CEO, Retail Council of Canada.

The Retail Council is a non-profit outfit representing more than 30,000 retail stores coast to coast.

The Council is often the first point of contact when a product recall occurs, Briseboise noted. “When working with retailers during those recalls, it became clear that without a national, harmonized system it was impossible to ensure the right people received the appropriate information in a timely manner, and the right product was removed or disposed of.”

If this doesn’t happen, or the retailer can’t provide proof that the recall has been properly executed, there could be serious legal and reputational consequences, she said.

The enhanced GS1 program reflects this emphasis on information standardization, authentication and security.

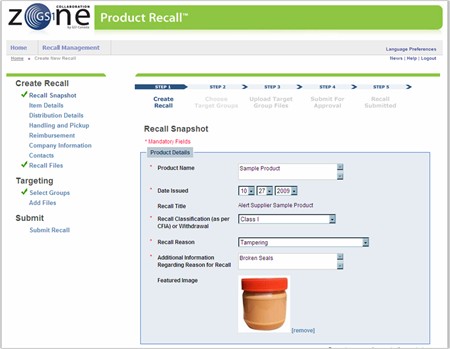

At the Toronto launch event, Tim White, director of product development at GS1 demoed key aspects of the system, which he played a key role in developing.

The program uses a series of questionnaire type forms that were built based on the input of Canadian businesses. They ensure that all the information that businesses consider essential is included in the recalls communications process.

Pillars of the program

Key pillars of the new program are: GS1 standardization, authentication and security. Citing a hypothetical example of the recall of peanut butter jars from a retailer, White showed how it all works in practice.

The business issuing the recall has to complete a standard online questionnaire providing information such as the product name, the recall date, product images, as well as any attachment associated with the recall, said White.

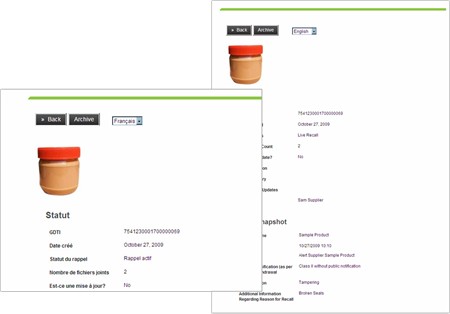

He then demoed the retailer view of the portal – the standard form accessed online by each participating retailer that’s populated with product recall information communicated directly from the manufacturer or distributor of the recalled product (in this case, the peanut butter).

Having this information available at one location, in standard format, is a far cry from the process in place until now, White said.

“We know from our discussions that in a product recall, retailers often receive multiple notices from several different sources. This creates confusion about which products are affected. Sometimes it results in unaffected items being pulled off the shelf.”

The new system, he said, eliminates ambiguity.

Through the portal each participating retailer is able to access comprehensive information that clearly identifies the item being recalled.

Information provided, he said, “includes the GTIN (global trade item number), product bar code as well as the cross-reference number at the bottom of the product so there’s no chance of the wrong item being pulled off the product right off the shelf.”

In addition, retailers can also access broader information including item details, distribution details, handling and pickup data, and much more. Retailers get to view this information in English and French.

“A powerful feature of this is the ability of retailers to communicate back to manufacturers telling them exactly how much product has been taken off the shelf,” said White.

Maile from Longo’s said the grocery retailer has already incorporated the new GS1 system into its recall processes.

But she clarified that this doesn’t change the way Longo’s handles a recall internally at the store level. “What it does ensure is in the event of a recall we get the critical information from vendors or suppliers that lets us execute the recall in a timely, accurate way. Our internal processes, however, will remain the same.”

The recall process

She outlined the process currently in place at Longo’s stores.

“The recall notification goes to our recall coordinator, who completes a form and e-mails it out to the store managers with the information they need to find the items in their system and pull them off the shelf.”

She said on receiving the e-mail, the store managers ask a team member within that department to pull the product off the shelves, take a count and dispose of the item in a safe manner.

“While that’s going on our recall coordinator also calls each store manager to ensure they’ve received the recall notice.”

Once the recall is completed, she said, forms are filled out by the “collecting” team member or “disposing” team member at the stores, as well as by the store manager. These are faxed to back to the recall coordinator on a designated recall fax machine line.

To roll out the new system, Maile said, no training was required at the store level. “Store employees just follow the same process they always have.”

But she said she and another person who receives recall information from suppliers were trained on the use of the new portal.

“Because we were part of the working group as well, we already had a strong knowledge going into the training of how the process works.”

For identifying some items on store shelves, she said, Longo’s uses Radio Frequency Identification (RFID) chips. “But we don’t use it for all items, because for some of our grocery products it’s difficult to use that kind of technology.”

And it isn’t just large or mid-sized grocery chains that can benefit the standardization offered by the GS1 product recall system.

The “enhanced” tool will also enhance communication with smaller shops, noted John Scott, president and CEO, Canadian Federation of Independent Grocers (CFIG).

He said CFIG, which has been around for about 50 years represents larger independent grocers, such as Longo’s and Highland farms, as well as some very small ones across Canada.

“To communicate with these small stores and communities countrywide, we needed an enhancement to the existing system, one that fostered accuracy and eliminated errors.”